MEIKO Technology

Shearing technology

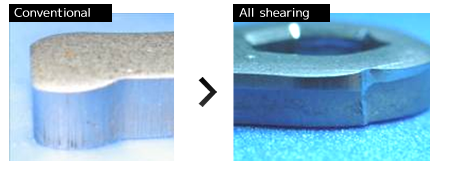

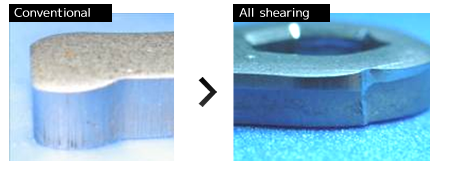

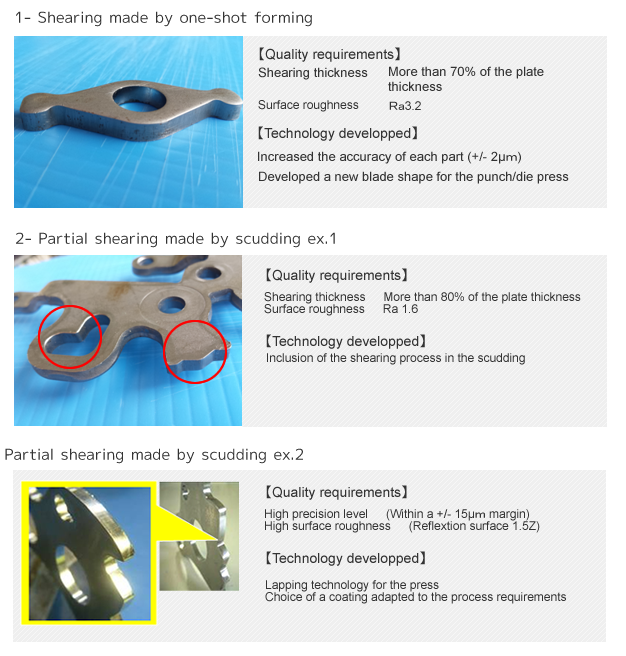

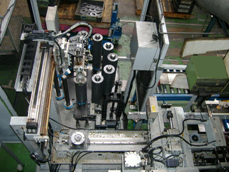

■Shear work made with a standard press

Untill now a fine blaking press was required for the shearing process. However thanks to the evolution of the molding technology, the possibility to do shearing with standard press machinery became possible contributing greatly to cost reductions.

[Shearing (one-shot process) made with a standard press (Type C 15t press, 1973 model)]

Untill now a fine blaking press was required for the shearing process. However thanks to the evolution of the molding technology, the possibility to do shearing with standard press machinery became possible contributing greatly to cost reductions.

[Shearing (one-shot process) made with a standard press (Type C 15t press, 1973 model)]

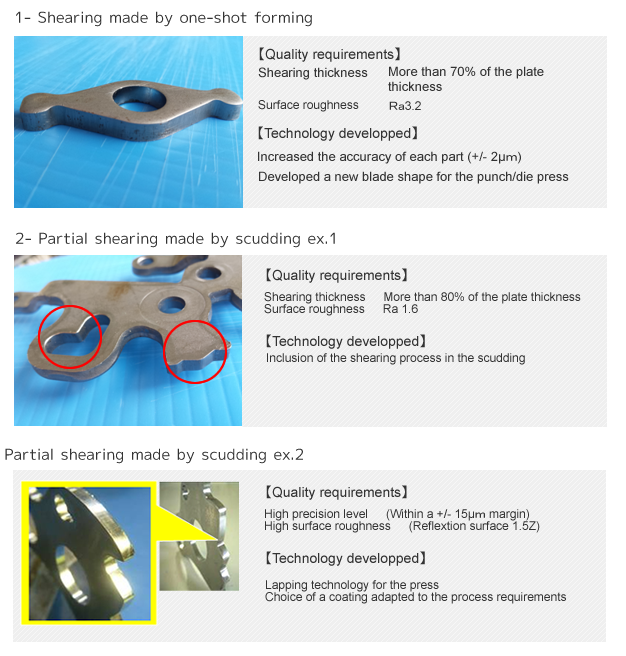

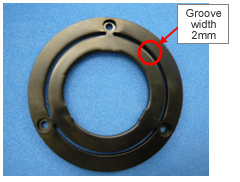

Groove processing technology

■Hole punching with a width of half the plate thickness

It is said for general hole punching that the limit is at 1,5 times the plate thickness.

We realized this hole grooving using process like punching etc.

【Product】

Aircon part for the Company T

【Quality requirements】

[Increased the punching resistance]

Starting Breakage with 3,000 units

Currently Abration replacement at 300,000 units

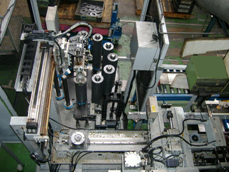

【Process】

1- External/boss shaping (scudding)

2- Long hole punching (one-shot)

3- Flatening (one-shot)

4- Circular hole punching (one-shot)

We designed ourselves the conveyor system and automatized the process using transfer devices (From october 2009).

It is said for general hole punching that the limit is at 1,5 times the plate thickness.

We realized this hole grooving using process like punching etc.

Aircon part for the Company T

| Material | SPHC |

|---|---|

| Plate thickness | 4.3mm |

| Groove width | 2.0mm |

| Production | 80,000 monthly units |

【Quality requirements】

| Width tolerance | SPHC |

|---|---|

| Boss shape ①Position precision ②Backside swelling |

Less than φ0.2 Less than 0.3mm |

| Flatness | Less than 0.2mm |

Starting Breakage with 3,000 units

Currently Abration replacement at 300,000 units

【Process】

1- External/boss shaping (scudding)

2- Long hole punching (one-shot)

3- Flatening (one-shot)

4- Circular hole punching (one-shot)

We designed ourselves the conveyor system and automatized the process using transfer devices (From october 2009).

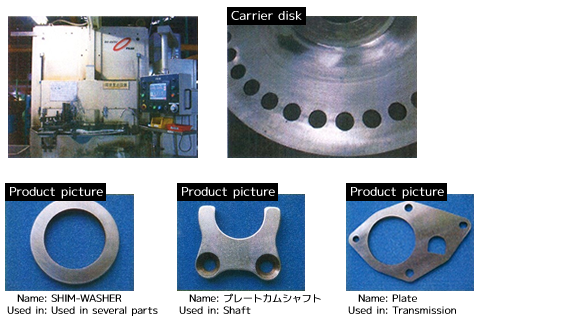

Wet-type double head polisher

【Equipment description】

To polish the part we insert it between grindstone using a rotating disk called a carrier.

■Characteristics■

・We can polish both side of the part by inserting it between two grindstone surfaces.

・High productivity by feeding the parts in the working slots of the carrier before inserting them between the grindstones.

・No interference between works avoiding breaking, splinters, chipping etc.

【Advantages】

・Maintain the plate thickness dimensions after the molding or easily maintain the flatness by eliminating the heat treatment strain.

・Easy setup making the process available for any kind of material.

・All the processes can be made in house reducing costs.

・By reshaping the carrier disk's slots the polishing process is not limited to washer shaped parts.

【Details】

Aircon part for the Company T

| Plate thickness | T=0.9~0.5 |

|---|---|

| Diameter | φ8 ~φ120 |

【Quality requirements】

| Parallelism | More than 0.02 |

|---|---|

| Plate thickness | +/-0.02mm |

| Surface roughness | Precision grinding: More than Ra 0.2 Standard grinding: More than Ra 0.4 |

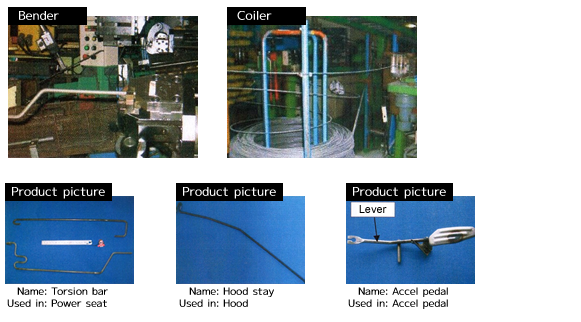

Wire forming

【Equipment description】

Once the coil material straightened with a roller, the wire is automatically sent by a control program to the forming machine which shapes the desired product curve by curve with a cam.

■Characteristics■

Untill now the bending of thick wire material was done from material requiring straight line cutting but this wire forming machine, developed in collaboration with the equipment manufacturer, can directly use coil material.

【Advantages】

・Because the forming can be done directly with coil material, the straightening process and cutting cost are not needed -> There is also no material loss.

・With in-line forming, step by step processing including up to the tempering treatment is possible.

・Operations being robotized, unmanned machining during the night can be done and production increased if needed.

【Details】

| Available steel type | SWM-B | Piano wire |

|---|---|---|

| Maximum diameter | φ4.5 ~φ10 | φ4.5 ~φ8 |

| Maximum product length | 1200mm | |

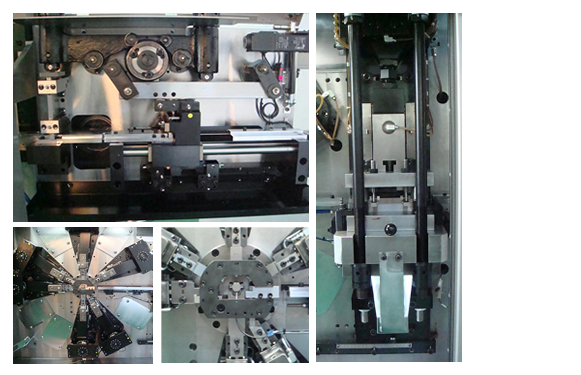

Multiforming

【Equipment description】

This machine being equiped with both a press mechanism and a bender, complex curve forming can be done in series.

Unlike usual cam type equipment, complex shapes can be easily done thanks to arms independently controller by servo-motors.

【Advantages】

Unlike with press machinery, as the forming can be made inside the material width, scrap occurences are low and a good material yield is obtained

The machine using servo-motors, there is no need to replace moving parts reducing the setup time and its cost.

"Setup time" cam type: about 4 hours → Servo-motor: about 1hour.

As complex processes are possible, a single machine is used for the forming where 2 were required until now (resulting in about a 50% cost reduction)

【Details】

| Material dimensions | Width | 50mm | Forming tool | Can mount up to 11 tools |

|---|---|---|---|---|

| Thickness | T 1.5 (SPCC material) |

Process SP | 1.5~2 time the cam type |